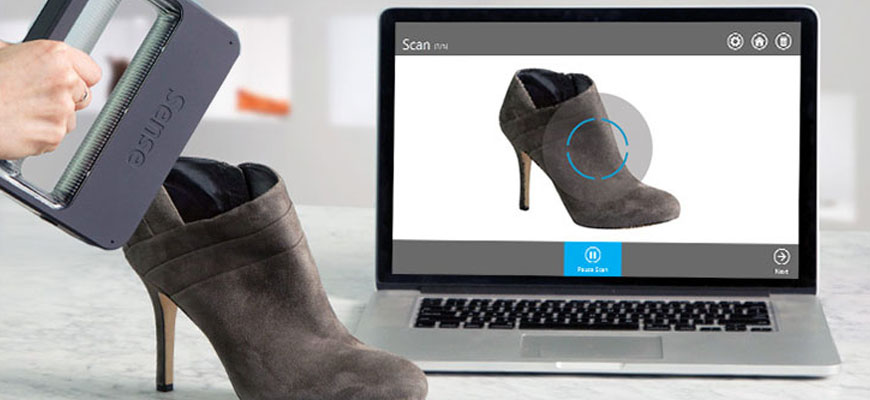

The process of converting physical objects into precise digital models, enables you to quickly and accurately capture your object’s shape and geometries. This process supplies you with a complete digital representation of your part to be used for reverse engineering, quality inspection or at any point of a typical manufacturing cycle.

Let 3D scanning empower you with: rapid data capture, shortened production cycles, increased manufacturing efficiency, improved product quality, CAD models that reflect shop-floor changes. 3D scanning can be used in almost any engineering process and/or setting, and as a result there are many different ways that the data obtained can benefit you. While most customers require post-processing of 3D scan data, it is not necessary in some situations.

Tell us your problem and we’ll do everything in our power to help you solve it. We are great project managers and are happy to perform large-scale service projects in addition to smaller projects. So whether you need simple STL data for 1 part, or class A surfaces of 500 parts, give us a call!

Let 3D scanning empower you with: rapid data capture, shortened production cycles, increased manufacturing efficiency, improved product quality, CAD models that reflect shop-floor changes. 3D scanning can be used in almost any engineering process and/or setting, and as a result there are many different ways that the data obtained can benefit you. While most customers require post-processing of 3D scan data, it is not necessary in some situations.